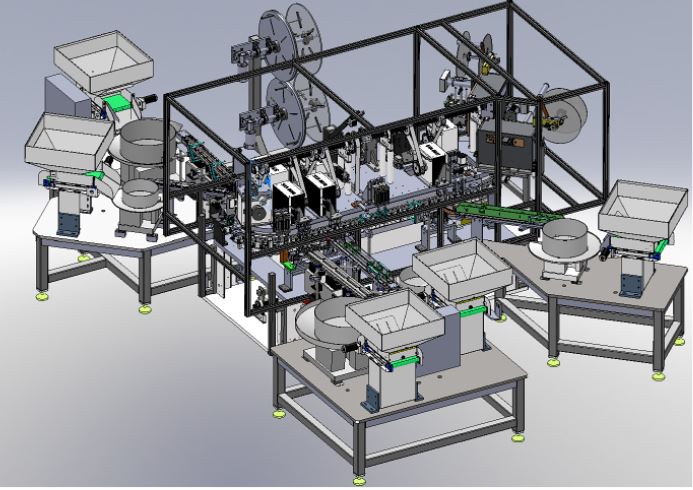

Fully Automated Lines

Fully Automated Lines

Fully automated production Lines for complex operations of product assembly and testing, equipped with state of the art safety systems, integrated with:

- Robots

- Manipulators

- Press fitting stations

- Bolts and screws tightening stations

- Test stations

- Conveyors

- Rotary Tables

- Tools

- Fixtures

- Boxes

- Bins

- Lightning

- Power Connectors

- etc.

PRO‘S:

- Low labor cost

- High productivity

- Fully automated key operations

- Material flow handled automatically

- Full quality control and product tracking

- Improved reusability and flexibilty (if Robots are used)

CON’S:

- High system cost

- Limited reusability and flexibility (if Robots are not used)